Can I use a 12V DC power supply on a 12V AC running on a few DC and a few volts of DC? For example, low-power applications using a few LEDs are appropriate for mobile phones powered by a DC battery. Although AC has several advantages, most LEDs are powered by DC, including new technology that allows AC to drive LEDs.

This needs electronics between the supply and the devices to create a DC voltage of 12V DC capable of driving many LEDs. The development of AC-LEDs, which run on AC power, is a novel method.

However, some applications require other considerations, such as a 100-meter linear strip lighting system around a structure. In addition, a DC drive suffers from distance losses, necessitating higher drive voltages and extra regulators that waste power.

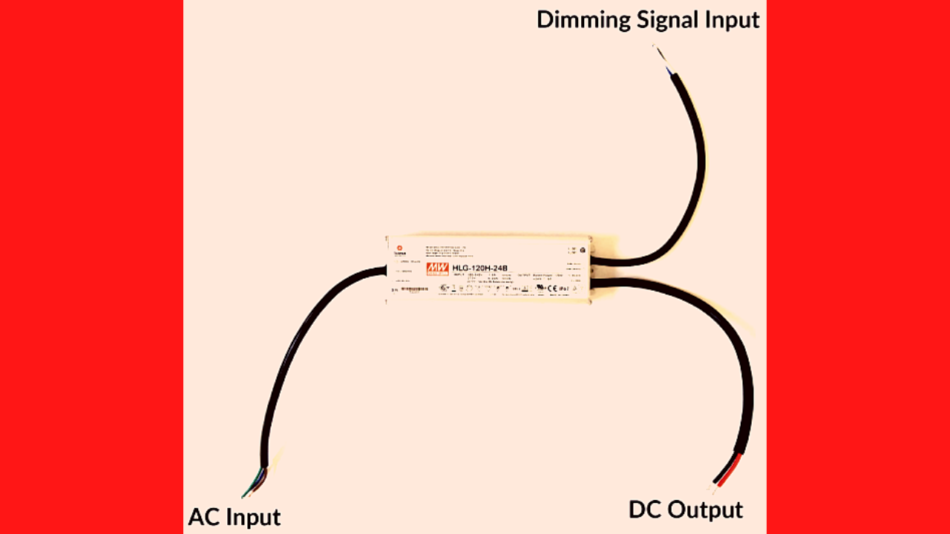

To run an LED-based fixture from 120 V AC, you must convert the supply to a DC voltage of 12 V DC capable of driving many LEDs.

The development of AC-LEDs, which run on AC power, is a novel method. With AC, electricity is transported and used more effectively; without complicated electronics to convert AC to DC. Putting LEDs right on end gives you a twofold advantage:

- The power was handled efficiently in the distribution environment.

- It was delivered more effectively without intervening in electronics.

Using an AC power supply to power LEDs

With an AC power source, there are several alternatives for running LEDs. Many LED lights merely need a transformer to supply the necessary DC power from the wall socket to the fixture. Some businesses have produced LED light bulbs that screw directly into conventional sockets. However, they always involve tiny circuitry that converts AC to DC before sending energy to the LEDs.

Another option is to use a DC bridge circuit to connect the LEDs or bulbs individually. However, even though AC powers this LED bridge circuit, the LEDs must be driven by DC, requiring more drive power than needed for the AC-LED design.

Those festive lights, like Christmas lights, are an example of an AC-LED system. In this example, the voltage drop across the string of LEDs is equal to the supply voltage.

There are two separate series-connected die lines in the AC LED gadget:

- One line is lit during the positive half of an AC cycle.

- The other occurs during the negative half.

The two separate die lines have been linked in two distinct ways. First, the LED seems active because the strings are alternately electrified and deactivated at the AC mains power source’s 50/60Hz frequency.

Controlled LEDs using capacitive current sensors

A capacitive current control LED is connected to and operated by a driver using constant-voltage/constant-frequency drivers. The capacitor eliminates resistive components, which reduces heat generation and enhances system performance. The capacitive current control LED gadget or assembly includes reversed LEDs and a matching capacitor.

Depending on the device or system architecture, the capacitive current control LED can deliver more brightness at the same power as utilizing the same die in a DC-driven resistor-based circuit.

A DC source typically powers a conventional LED device, and the driver circuit contains a resistor to ensure the proper voltage drop across the emitter in the simplest version. As an alternative, the capacitive current control LED technique connects an AC supply to a circuit that contains a capacitor and an even number of LEDs or dies. The system uses both half cycles of the AC wave to its fullest potential.

For maximum efficiency, capacitors and LEDs in multiples of 2 or more are used in a typical capacitive current control LED device. The capacitor decreases the voltage and acts as a resistor for the LEDs. Capacitance can provide continuous voltage and frequency to LEDs, separating them from other LEDs and their driver in the case of a failure.

The AC-LED driver or power source may power both devices above, despite needing different voltages and currents. In addition, this capacitive current control LED method further enhances thermal management and efficiency by removing the resistive component from the DC circuit.

System Security

It also adds to dependability. For example, a 24V DC driver transmits 1.4 A across 4 parallel strings of 350 mA LEDs in a DC circuit. However, if one string fails, the driver produces 1.4 A or 467 mA per string. AC-LED technology can avoid this undesirable over-current condition. For example, a 12V AC supply gives 350 mA to four capacitive current control LED strings, each with six emitters. The driver supplies a constant voltage and frequency, while the capacitor regulates the current in each string.

Luminosity

Preliminary results show that the capacitive current control LED can give more brightness for less electricity. This is because the LEDs have a lower junction temperature since they are only active for one-half of the AC cycle.

Conclusion

However, AC performs better over long distances, so it is used to power homes and companies worldwide. Using transformers to reduce the voltage from kilovolts to 240 or 120 volts AC is easy with AC, but not with DC.